Welcome!

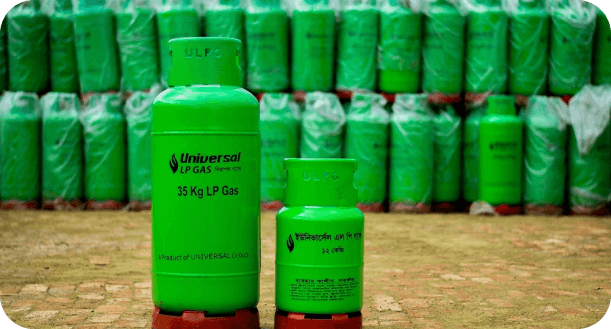

Universal Group comprising of a good number of business entities-Universal Gas & Gas Cylinder Limited, Universal Agency, US Energy and Power (Pvt.) Limited, Universal CNG & Petrol Pump, Universal RS Engineering Pvt. Limited AMB Traders Pvt Limited, Global Survey & Inspection and MS Enterprise engaged in manufacturing, service and trading business has been operating with good reputation for around 32 years since 1990 and by this time has successfully been able to create a unique brand especially in the domain of LPG business in our country under the very competent leadership of experienced management with diversified expertise and understanding. Manufacturing and supply of LPG gas cylinder, LPG gas supply to household and industry, gas station for vehicles, LPG reticulation system set-up, import and trading of bitumen, coal and stone, Clearing and Forwarding service, CNG,LPG & Diesel filling station constitute our core businesses. Apart from this, we are` the registered procurement provider of DGDP (Directorate General Defense Purchase), MES (Military Engineer Services), CMTD (Central Mechanical Transport Depot) and LGED (Local Government Engineering Department). Apart from these, we operate as the licensee in the name of Global Survey and Inspection to carry out the survey of different types of vehicles related with insurance claim.

Emergency Delivery

Contact : 01682725555,01854454554

For this aforesaid business, we have at present following set up and infrastructure:

- 1) LPG mother terminal and Storage Tank with LPG Filling line/bottling plant at Nadalia, Barabkunda, Sitakunda, Chittagong, Bangladesh

- 2) LPG Storage Tank with LPG Bottling Plant at Kaichutty, Chouddagram, Cumilla, Bangladesh

- 3) LPG Cylinder Manufacturing Plant at Kaichutty, Chouddagram, Cumilla, Bangladesh

- 4) Bitumen decanting plant at Kaichutty, Chouddagram, Cumilla, Bangladesh

- 5) LPG cylinder depot and distribution point at Arihazar, Narayangonj, Dhaka, Bangladesh

.png)

Rafiqul Islam

Rafiqul Islam